Case Study 8

Wärme Lyss Nord District heating

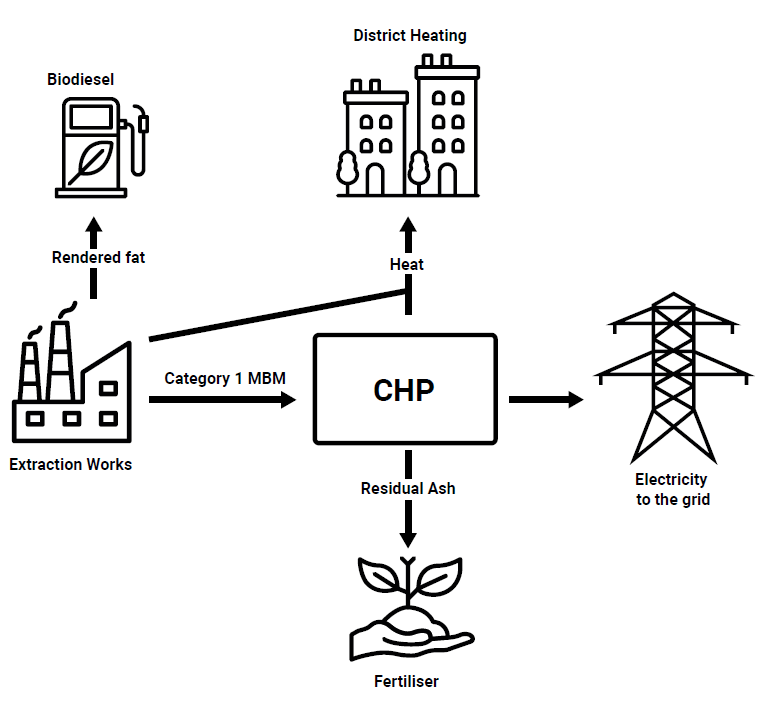

Products from the GZM Extraktionswerk AG Category 1 ABP processing facility in Lyss, Switzerland are used as renewable fuels and the heat and power produced are supplied to the Wärme Lyss Nord district heating scheme and adjacent industrial processes. The district heating scheme provides local residents with sustainable, environmentally friendly and cost-effective heating and replaces fossil fuels such as oil and natural gas.

The GZM Extraktionswerk AG rendering facility safely processes Category 1 ABP raw material and produces MBM and animal fat.

The animal fat is sent to a biodiesel production unit while the MBM is used as a biomass fuel in a combined heat and power coupling unit (CHP) which produces heat energy for supply to the district heating system. The evaporated water component of the ABP raw materials from the rendering process is captured as hot water and supplements the district heating supply.

“The district heating scheme provides local residents with sustainable, environmentally friendly and cost effective heating and replaces fossil fuels such as oil and natural gas”

The electricity generated by the CHP is fed into the grid and used by neighbouring industrial processes. Applying high efficiency modern turbines at the CHP reduces heat loss during energy conversion. An additional environmental advantage of the CHP is that the residual ash from the combustion of the MBM is rich in phosphorus and can be used as fertiliser in place of synthetic fertiliser.

On the basis of the supplied energy of the processing plant being about 23 GWh, it is possible to save up to 2 million litres of fossil oil equivalent, saving around 6000 tonnes of CO2 emissions into the environment, a significant contribution to a low-emission heat supply.

Case Study 8 - Version 1, October 2021