Case Study 15

Creating sustainable products from porcine bones

Sonac Vuren, part of the Darling Ingredients Group in the Netherlands process food grade porcine bones to create several high value products with a range of applications.

The Sonac Vuren installation has a bone degreasing line, similar to rendering and a protein extraction line, similar to a gelatine process.

Food grade raw materials are sourced from porcine bones as a by-product from the meat industry. All raw materials are from healthy animals, approved ante and post-mortem and fit for human consumption.

In the pre-treatment or bone degreasing stage the raw material is washed and chopped. Then the bone chips are cooked to transfer the protein from the bones into water. The dissolved proteins are then carefully hydrolysed with the use of enzymes, concentrated and spray-dried. Afterwards, the protein and mineral particles are optimised to create a uniform powder.

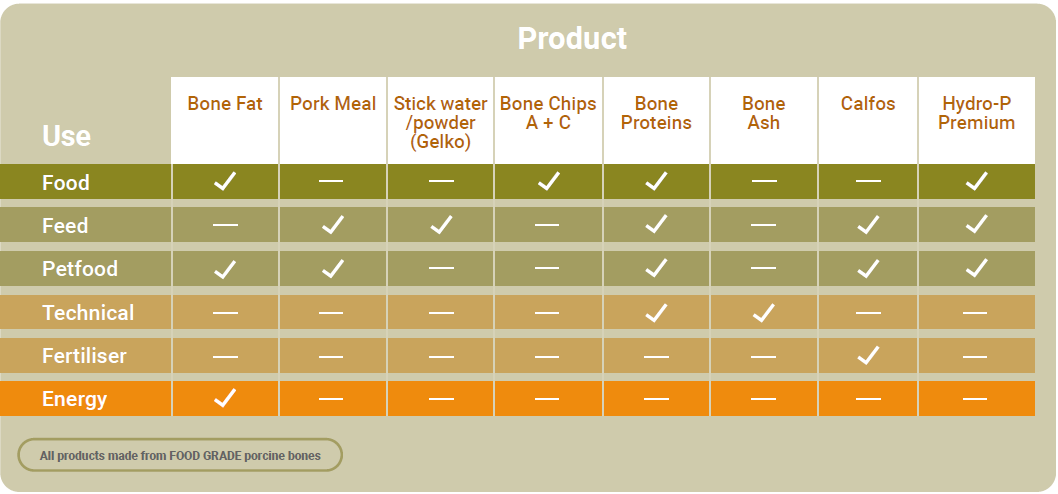

The bone degreasing line produces bone fat, bone meals and stick water / powder called Gelko. The protein extraction line produces bone chips, bone proteins, bone ash and a hydroxyapatite called Collaphos. A further stage produces a collagen hydrolysate called Hydro P Premium. These products have various applications as illustrated in the figure below:

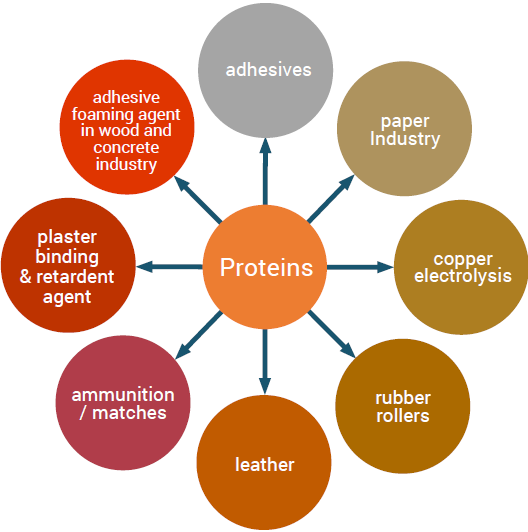

The primary applications are in food, animal and pet feed, energy and fertiliser but there are also some interesting technical applications such as in bone

china ceramics, nonferrous foundries and other industrial applications as illustrated in the figures below.

The interactive content below might not be fully accessible.

The interactive content below might not be fully accessible.

Case Study 15 - Version 1, October 2023