Case Study 12

Renewable nitrogen fertiliser from wastewater

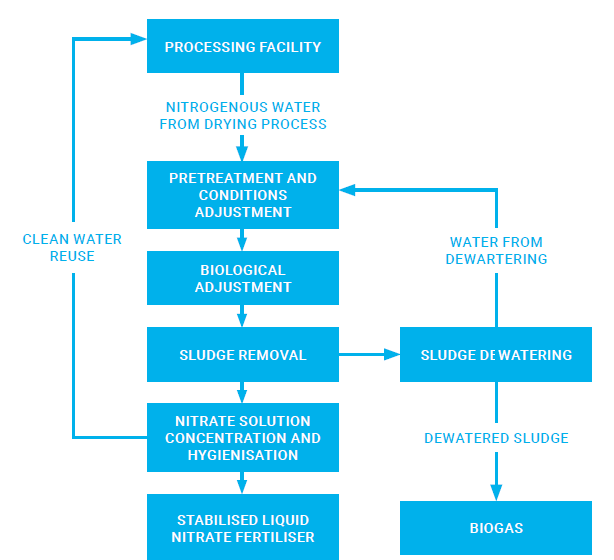

Animal by-products have a high moisture content (around 65%) which is evaporated during processing by rendering. This vapour is condensed and the resultant nitrogen rich condensate is collected. Where there is no further application for the condensate it is typically combined with wastewater from the site and sent for treatment in a wastewater treatment plant.

Honkajoki processes this ammonia-rich condensate separately to produce a renewable nitrogen fertiliser and clean water, available for reuse on site or in other applications. This reduces the volume of wastewater to be treated dramatically.

Unlike most renewable fertilisers which are ammonium-based and require a nitrification step in the soil, this product contains nitrogen as nitrate which is immediately available for the crop to use.

"Our biological nitrogen fertiliser process creates a sustainable product from wastewater treatment."

Many types of process wastewater can be used and the revenue from this sustainable product and the reduced water consumption gives added value to this essential, but otherwise expensive process step. Where deployed in water scarce areas the clean water produced is a valuable source of water.

The organic nitrogen fertiliser production solution has been developed at Honkajoki by wastewater treatment specialist Flownord, together with Honkajoki’s technology and consultancy subsidiary GMM Finland.

The biological process for producing nitrogen fertiliser can be retrofitted to many types of existing biological water treatment facilities. It can be adapted to work with various kinds of nitrogen-rich effluents.

Case Study 12 - Version 1, October 2023