Case Study 13

Heat recovery from hides and skins processing

Since ancient times hides and skins have been a valuable by-product of livestock farming and their utilisation in the leather industry continues to this day.

The hides and skins of Swiss cattle, calves, lambs and sheep are used for producing exceptionally highquality leather products. The outstanding quality of the Swiss hides and skins is related to the high Swiss animal welfare standards and climate conditions, especially in the Alpine regions.

All hides and skins in Switzerland are collected on a daily basis from slaughterhouses and transported to the Centravo hides and skins facility at Lyss, Switzerland. Each year around 850,000 hides and skins (16,000 tonnes) are collected, prepared and preserved by Centravo using craftsmanship and sophisticated computerised process control systems for further processing in European tanneries or for global exports.

Upon arrival at Lyss the hides and skins are still warm (around 27°C) and are stored in a cold room for 24 hours. In 2017 Centravo installed heat pumps to recover the residual heat from the hides and skins and this now supplies all the facility’s heat, replacing natural gas which is no longer needed.

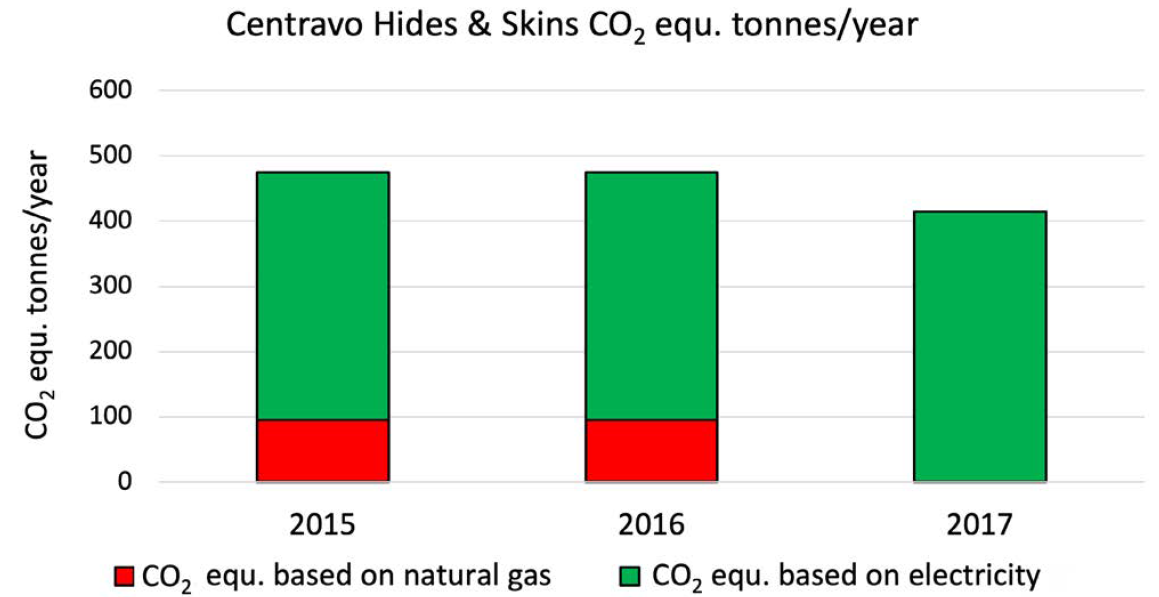

The graph below shows that the Carbon Footprint of the facility has reduced significantly by around 70 tons/year of CO2 equ. Values are based on the CO2 Calculator of the Federal Environment Agency, WWF.

"To achieve a Centravo target for a climate neutral facility a further project is looking at generating electricity from on site photovoltaics.”

Case Study 13 - Version 1, October 2023